COPYRIGHT © NANTONG RONGHENG 苏ICP备10211114号 Powed by 300.cn

C series multistage centrifugal fan

The multi-stage centrifugal blower products produced by our company have a place in the domestic sewage treatment, flue gas desulfurization, denitrification, vacuum drying, powder and granular transportation, coal and coal washing, nitrogen pressurization, biogas increase, circulating heating and other fields.

Through continuous technological innovation, our company has newly developed a high-efficiency multi-stage centrifugal (turbine) blower. Its high efficiency, energy saving, low noise and other advantages make it a blower product with better performance and lower price in China. The product strictly implements GB/T28381- The 2012 National Standard of "Limited Values of Energy Efficiency and Energy-saving Evaluation of Centrifugal Blower", and passed the test of Nantong City Product Quality Supervision and Inspection Institute.

Our company now has a number of patented technologies with independent intellectual property rights, and has successively won honors such as "High-tech Enterprise", "Private Technology Enterprise in Jiangsu Province", and "High-tech Products".

Features

1. Light weight

Compared with the same type of blower, the weight is 30% lighter.

2. Low noise

The noise of the blower body is less than or equal to 84dB(A), and it is high-frequency noise. When there is no soundproof room, the propagation distance does not exceed 20 meters

3. Small vibration

Under operating conditions without any vibration reduction device, the radial (bidirectional) vibration speed of the blower bearing seat is ≤4.0mm/s.

4. No mechanical friction

When the blower is running, there is no mechanical friction between other parts except the bearing, which reduces the noise and ensures the service life.

5. Oil-free machinery

No oil or gas is generated during the operation of the blower, and the aerator is not corroded, which prolongs the service life of the aeration system.

6. Shaft temperature digital display sound and light alarm

The front and rear bearing housings of the fan body are equipped with thermocouples, and the ports are connected to a digital display to display the shaft temperature. The temperature of the bearing will rise due to lack of or overfilling of grease, oil, or wear. When the set temperature is exceeded, the sound and light alarm will automatically alarm.

7. Easy maintenance

Since the centrifugal blower is a frictionless machine, the rotor is supported by the front and rear bearings, and the casing and impeller are not easily damaged. Daily maintenance is mainly to ensure the effective lubrication of the bearings and temperature monitoring. Normally, only the replacement of bearings and couplings is required. Stud. The blower casing adopts a series connection structure (similar to a string of candied haws), the front and rear bearing seats are independent, and the external (connected with bolts) are connected to the intake and exhaust volute. When repairing, there is no need to disassemble the whole machine, just unscrew the connecting bolt and remove the bearing seat to replace the bearing, saving time and convenience.

8. Case water cooling

For the blower whose pressure is higher than 8mH2O, because the temperature at the outlet end must exceed 160℃, a cooling spacer is added to the outer layer of the casing (stator), which can reduce the gas temperature by more than 40℃, effectively increasing the blower’s pressure rise Efficiency and overall work efficiency. The water source can be connected in series with the water cooling device of the bearing housing. The water consumption is less than 1.5m3/h, and the water consumption cost is much lower than the electricity cost saved due to efficiency improvement

9. Inverter control

For a blower equipped with a 380V low-voltage motor, a frequency converter can be used to increase the power frequency and increase the speed to 3600rpm, thereby increasing the blower efficiency to 80%. After frequency conversion, energy consumption can be greatly saved. In particular, the booster and flow rate adjustment range of the blower can be larger, and the application range of the unconstant water level such as SBR is wider. It has the advantage of flushing due to partial blockage of the aerator, especially the blower below 45m³/min can reach about 11mH2O Boosting effectively solves the problems of small flow and high pressure processes such as deep well aeration.

10. Easy to install

The complete blower is delivered from the factory. The main engine and the motor are fixed on the same steel base. There is no need to add other damping devices in the installation, and the requirements for the installation level are not high. The filter muffler at the inlet of the blower can be directly installed on the blower; and the outlet pipe must be connected to the blower through a flexible joint to prevent the gravity of the pipe and the additional force of installation from directly acting on the blower.

11. The rotor is manufactured with advanced technology

The impeller uses finite element theory and adopts quasi-three-dimensional (ternary flow) design. The impeller is made of high-quality aluminum alloy by centrifugal casting; stable and reliable performance, ensuring the strength of the impeller under high-speed operation, so as to ensure the longest service life of the impeller. Because the impeller line is reasonable and well made, the blower efficiency reaches 78%, which saves a lot of energy and reduces operating costs.

12. Rear bearing housing water cooling

In the process of blower, due to the compression of air, the temperature of the final casing is generally higher than 80 ℃, and the temperature of the Xia Li can be higher than 100 ℃, so the bearing seat cooling needs to be considered. In the original design, the rear bearing seat air-cooling system has been installed, and now we are innovating on this basis, adding a water-cooling system, realizing the dual insurance function of the rear bearing seat and extending the service life of the bearing. The quality of the cooling water is not high, tap water, reclaimed water, or even preliminary treated sewage can be used.

Fan performance guarantee

1. The design and structure of the blower and auxiliary equipment ensure a service life of at least 20 years and an uninterrupted operation time of at least 18 months.

2. the quality guarantee period is 12 months after delivery, lifetime service.

3. The blower has undergone performance testing before leaving the factory to ensure that the blower’s performance meets the national standards.

4. The fan is designed to avoid surge, abnormal noise, abnormal vibration, abnormal temperature rise, or actual power greater than motor power under the premise that the pipe network resistance under working conditions is less than the working pressure of the blower.

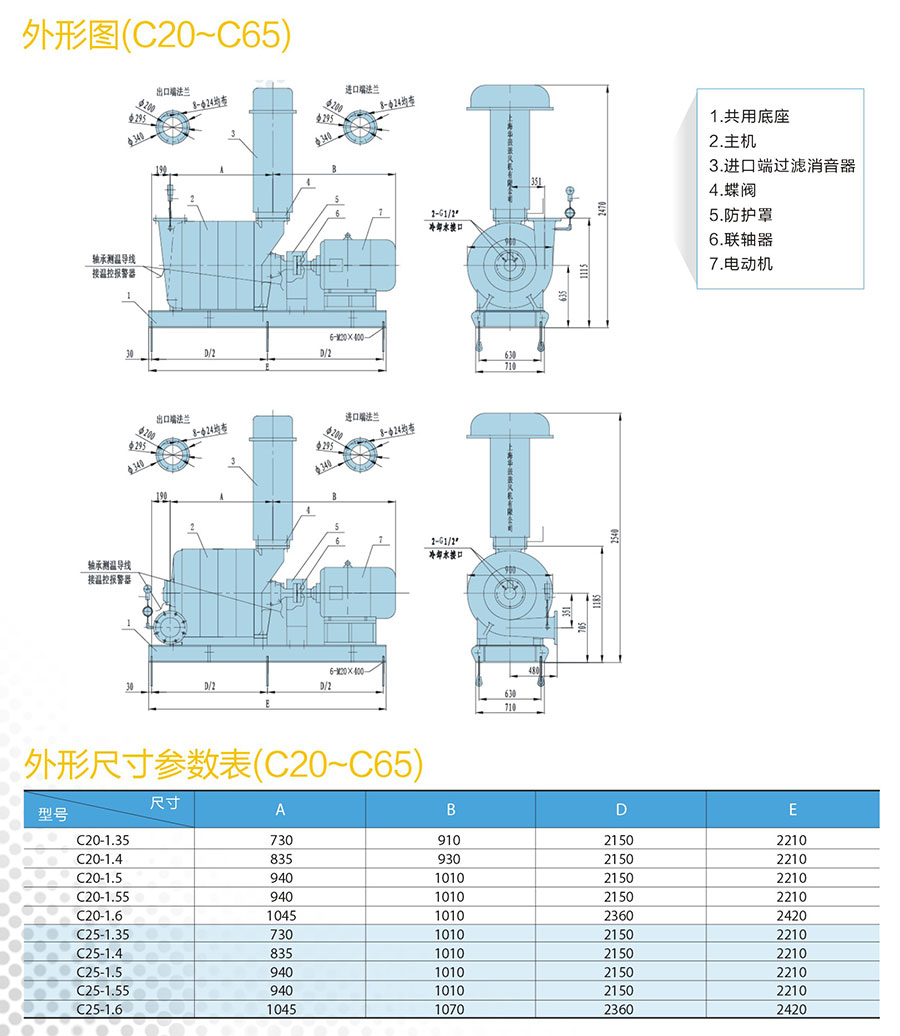

Model Description

Main technical specifications of C series products

Inlet flow rate: 15-1500m³/min

Outlet pressure: 1000-12000mmH2O

Environmental temperature: -35~+40℃

Relative humidity: 20~85%

Noise: ≤84dB(A)

Bearing seat vibration value: vibration speed ≤4.0mm/s

C series centrifugal blower performance table